Facilities

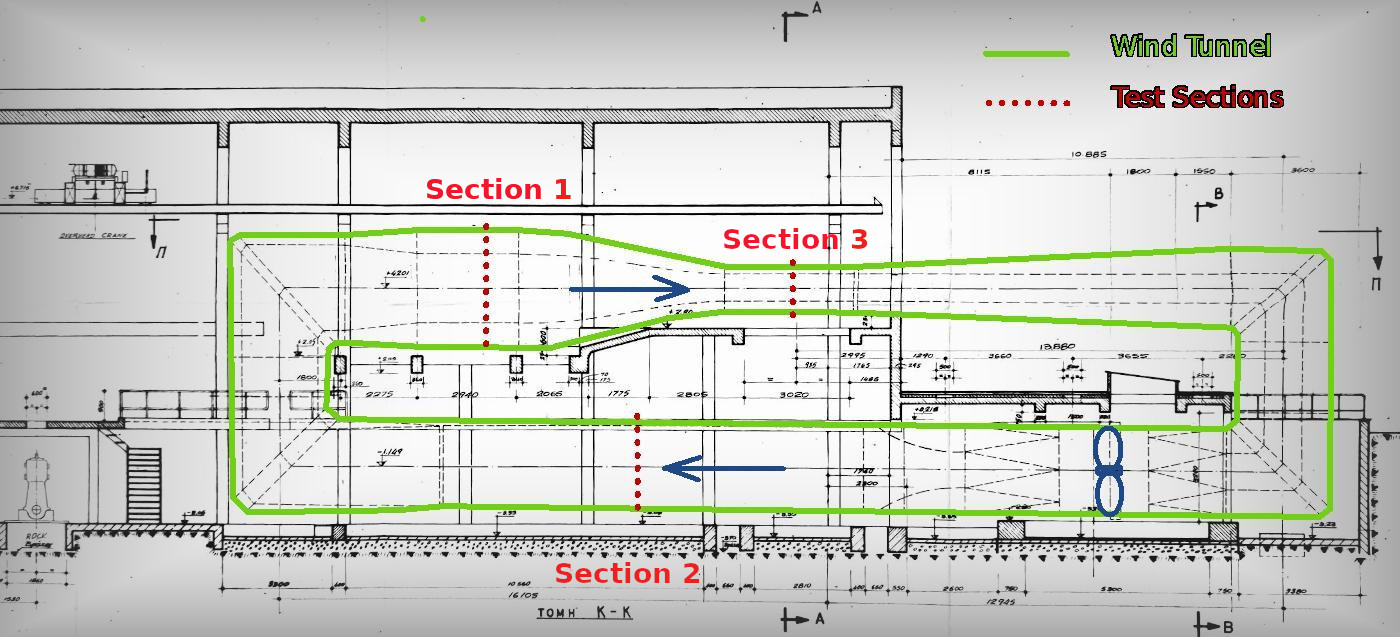

The Wind Tunnel sections and a selection of the available equipment is presented.

The total length of the wind tunnel is 32m and it consists of 3 test sections:

| Section | Width (m) | Height (m) | Max. speed (m/s) |

| 1 | 4.5 | 3.5 | 9.5 |

| 2 | 3.5 | 2.5 | 17.0 |

| 3 | 1.8 | 1.4 | 60.0 |

Test Section 1 (4.5x3.5m)

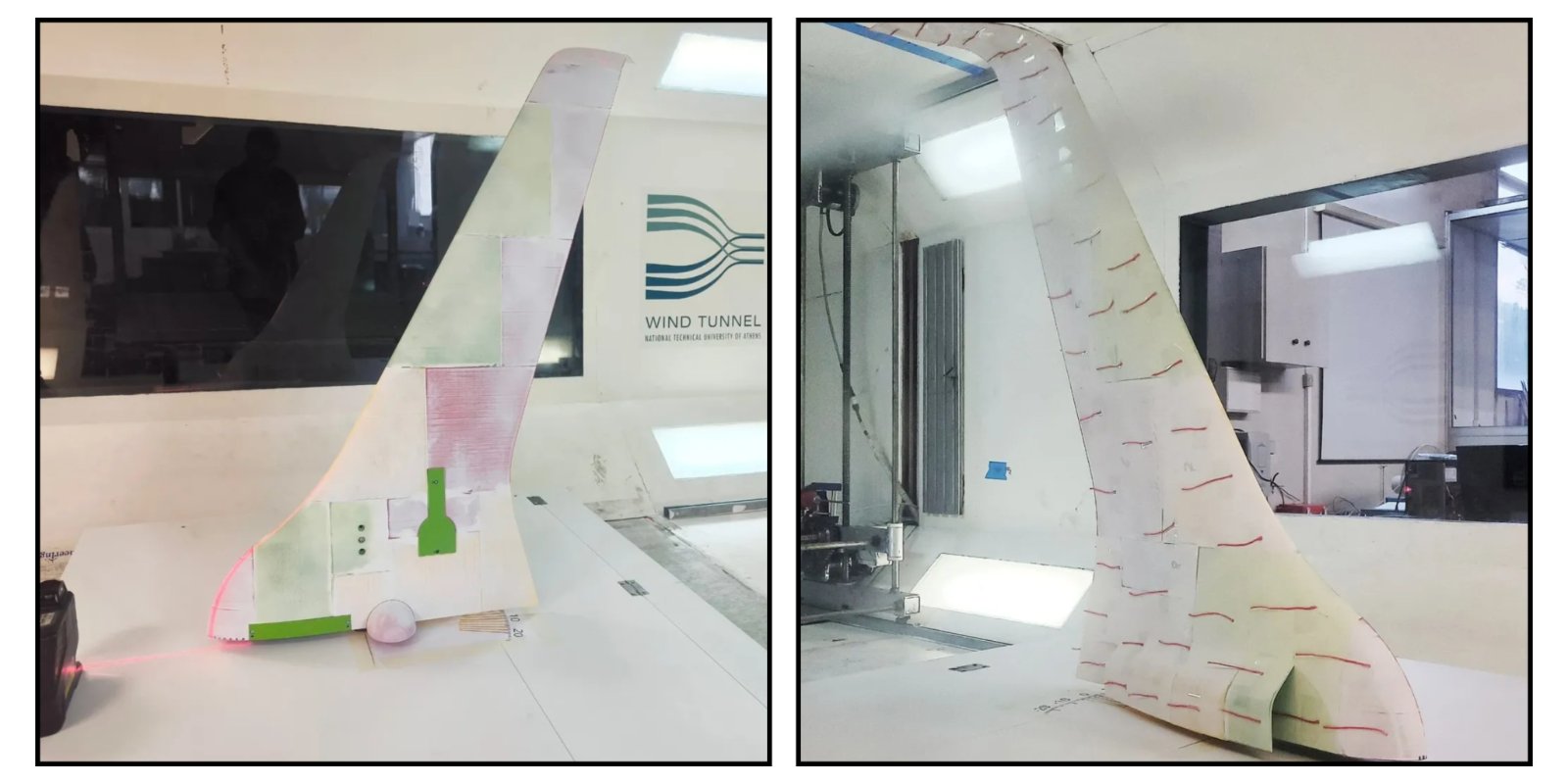

The first wind tunnel section (largest) is suitable for testing small propellers, wind turbine rotors, fans and small sails.

MORE

Test Section 2 (3.5x2.5m)

The second wind tunnel section is equipped with a remotely controlled turn table floor, a three directions motor driven remotely controlled traversing mechanism and a high accuracy six-component balance for the measurement of the airloads.

MORE

Test Section 3 (1.8x1.4m)

The third wind tunnel section is suitable for basic and applied research applications. It can be used for testing 2D aifoils, aircraft wings, fuselages, model aircrafts, light and heavy vechicles. It is equipped with a high accuracy six-component balance for the measurement of the airloads.

MOREA variety of measuring techniques can be used in the Wind Tunnel with respect to the needs of the examined case:

- A PIV system is available, allowing velocity field measurements on a plain.

- Load measurements are performed using a 6 component balance and a 6 component load pad.

- Localised flow velocity measurements are performed by means of hot wire velocimetry and 7 hole pitot tubes.

- A Laser-Doppler apparatus is available for measuring fluid velocities with the use of laser beams, based on the Doppler frequency shift of the optical signals. The LDA technique has been used in pulsating flows in closed ducts of small dimensions (expanding or contracting and, branching ducts) in which the blood circulation is simulated.

- Multiple channels pressure scanners are available for measuring static pressure distributions on aerodynamic bodies.

- Flow visualizations are performed using smoke and a Laser source, liquid crystals and ΤiΟ2-oil compound.

Next, a selection of the available instrumentation and devices that are used for the abovementioned techniques is presented.

Kistler, Multicomponent Force Plate, Type 9253B

Kistler, Multicomponent Force Plate, –15 ... 30 kN, mounting plate 600x400 mm, Type 9253B.

MORE

Furness, FCO432 Differential Pressure Transmitter

The Furness FCO432 is a fully configurable, industrial differential pressure transmitter, suitable for industrial applications of control, measurement and monitoring.

MORE

microDAQ 2 Smart Pressure Scanner

The microDAQ2 is a further development of the well- established Chell microDAQ system. The microDAQ2 is a complete acquisition system giving the user fully calibrated, temperature compensated data on easy to use Ethernet and CAN interfaces.

MORE